Straton Advantage:

From Quote to Delivery: Your Full-Service Manufacturing Partner

Complete Manufacturing Solutions — Engineered, Built, and Delivered.

What sets Straton Industries apart is our vertically integrated, full-service manufacturing capability. We oversee the complete production lifecycle—from initial request for proposal (RFP) and design-for-manufacturability (DFM) engineering, to CNC machining, multi-axis fabrication, precision assembly, in-process and final quality inspection, and on-time delivery.

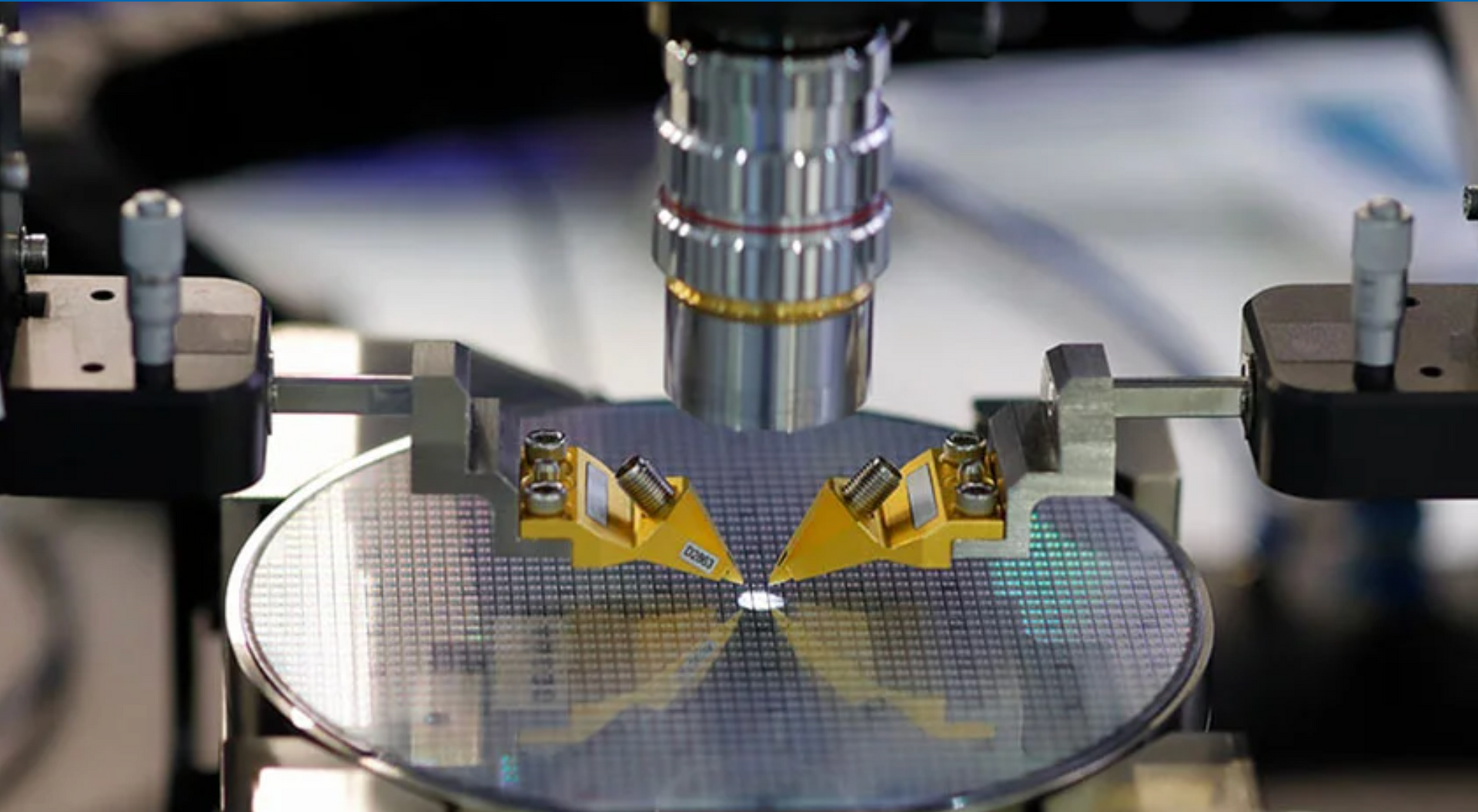

Our ability to manage every phase of the manufacturing process under one roof enables us to maintain tight process control, reduce lead times, and ensure consistent quality across highly complex and regulated projects. Customers across aerospace, defense, and semiconductor industries choose Straton Industries as a strategic partner for our technical depth, responsive project management, and commitment to delivering precision-built components from concept to completion.

Built on Precision. Driven by Partnership

Straton Industries has cultivated long-term relationships with global leaders in

Aerospace & Defense,

Military, and

Semiconductor sectors by offering something few others can:

a fully integrated, end-to-end manufacturing solution—from concept to delivery.

Unmatched In-House Capabilities

Our vertically integrated facility gives product development and engineering teams the tools to move fast and build smarter. With advanced CNC machining, exotic metals expertise, precision assembly, and rigorous in-house quality inspection, we deliver mission-critical components with speed and consistency.

Precision-Driven Manufacturing Solutions

We deliver precision manufacturing solutions across the full production lifecycle. From DFM support and multi-axis CNC machining to FAA-certified repairs and lights-out production, our services are built to meet complex engineering demands with speed, accuracy, and reliability.

Straton Industries is a trusted manufacturing partner to leading global organizations, including ASML, General Dynamics, Kaman Aerospace, Lockheed Martin, and Sikorsky Aircraft. Our longstanding reputation is built on the consistent delivery of high-precision components manufactured to exacting tolerances and rigorous quality standards. Since 1961, we have supported critical applications across aerospace, defense, and semiconductor industries—exceeding customer expectations through technical excellence, process reliability, and an unwavering commitment to quality.

Our Manufacturing Process

RFQ & Quote

We analyze customer requirements in detail and generate a precision-aligned quote based on RFQ specifications for customer approval.

Process Planning

Once the purchase order is received, our engineers initiate process planning to define the most efficient, cost-effective manufacturing workflow.

Engineering

Our engineering team translates the process plan into detailed technical and machining specifications, while coordinating all external special process vendors to ensure compliance and efficiency.

Production

Our expert team manages the entire manufacturing workflow and external vendors, ensuring seamless execution and delivery of products that meet or exceed specifications.

Quality Inspection

Continuous in-process quality control is performed, culminating in a comprehensive final inspection by our dedicated QA team prior to shipment.

Pack and Ship

Finally, the project is securely packaged and shipped per customer-specific requirements.

High-Precision Machining and Precision Manufacturing

Enhance the reliability, performance, and innovation of your semiconductor devices.